Hydropower generation

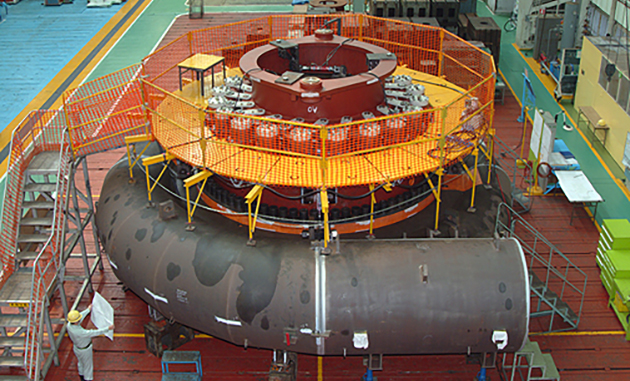

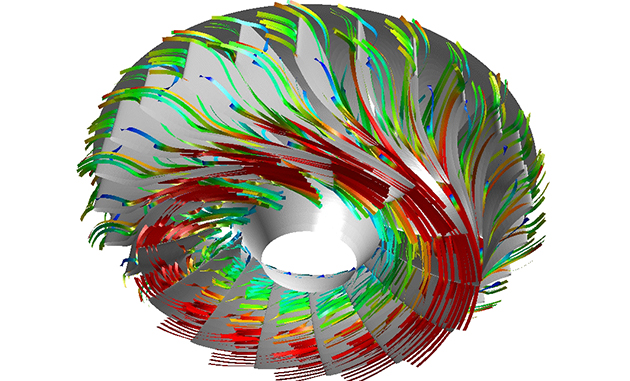

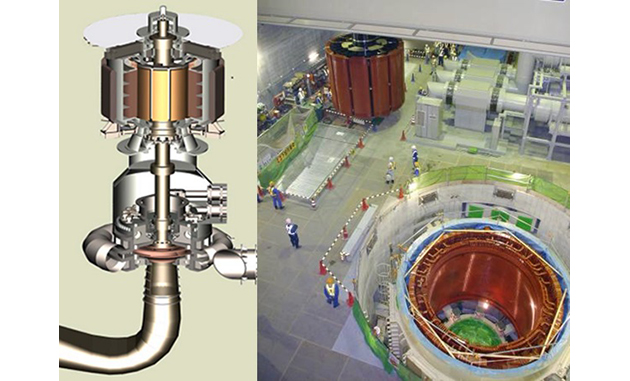

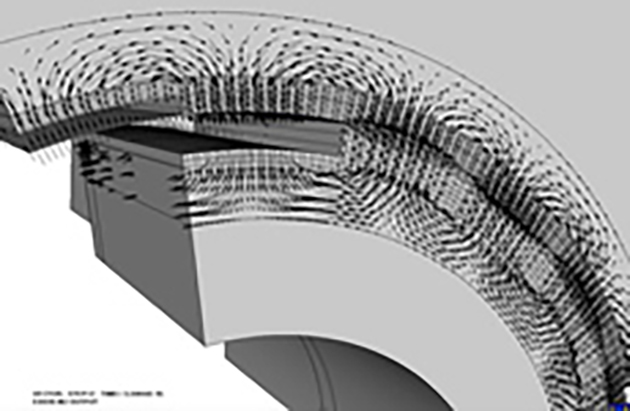

Turbines are the engines of a hydroelectric power system. Based on high reliability underpinned by extensive experience, the Hydroelectric Power Systems Division undertakes planning, development, design, fabrication, installation, and commissioning of turbines. By getting involved from the design stage of new power plants, the division helps create the optimum hydroelectric power plant for a particular site.Hitachi optimizes the design of each of its hydroelectric power plants to ensure that the water resources are utilized effectively.The collective expertise of Hitachi 's engineers helps protect the environment.