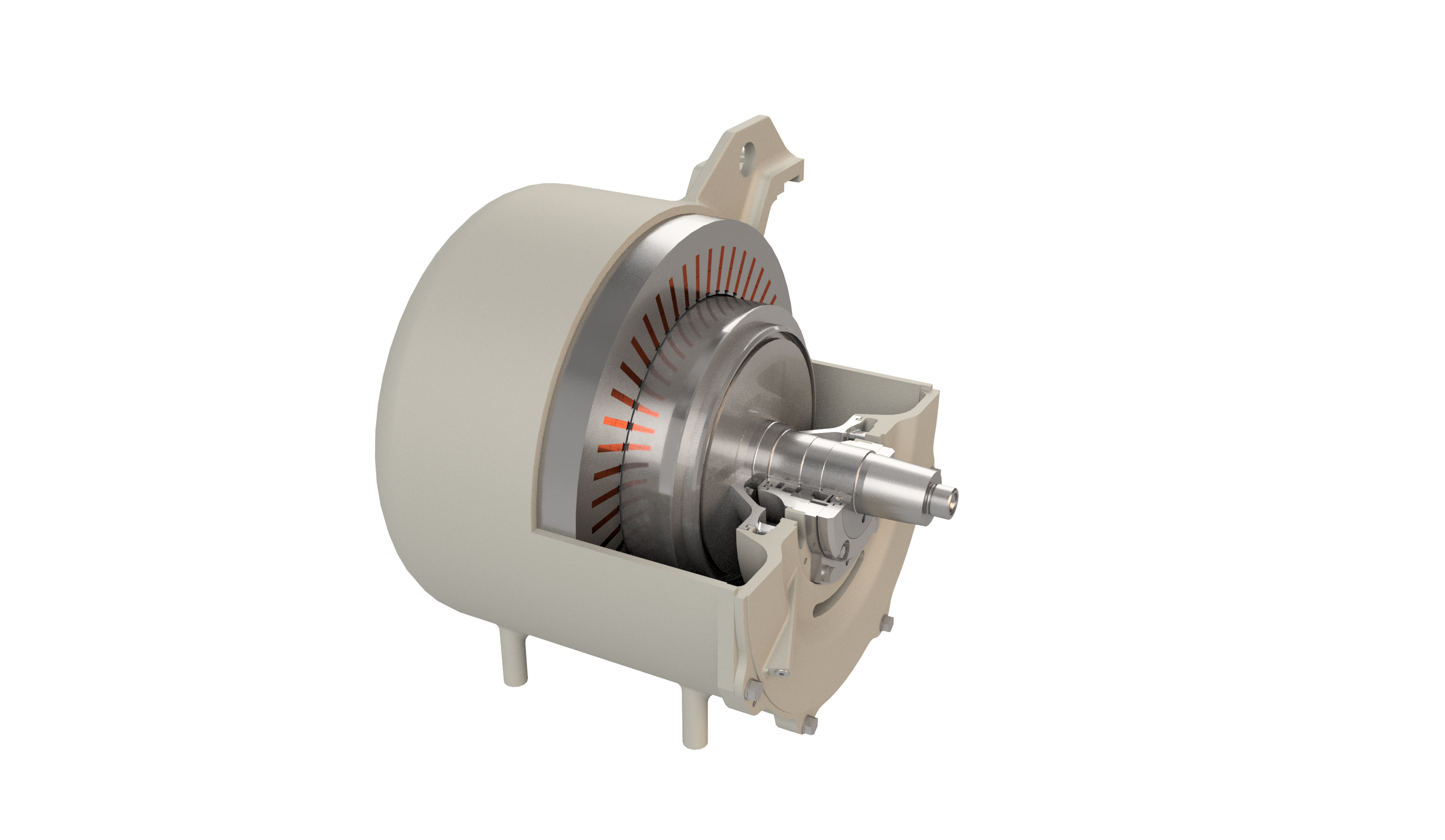

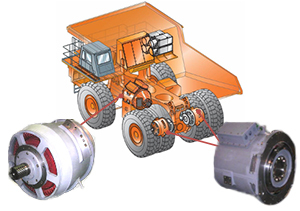

General industrial electric motors, power generation, wind power field

Hitachi has been promoting the evolution of electric motors, a product that we have provided since our founding, through our design and production technologies supported by tradition over more than 100 years. As a result, the electric motors of Hitachi are used for various purposes as a key device supporting social infrastructure in a broad range of applications, such as in power generation, industry, and transportation. Furthermore, we have incorporated the advances in IoT and digital technologies in recent years to utilize Lumada, solutions of Hitachi for accelerating digital innovations, to analyze product operation information and develop diagnostic technologies that forecast when devices need to be replaced. With this integration of products and digital technologies, we will continue providing new value to suit the needs of customers throughout the entire lifecycle of products, from design to operation and maintenance.